PCB Handling Conveyors

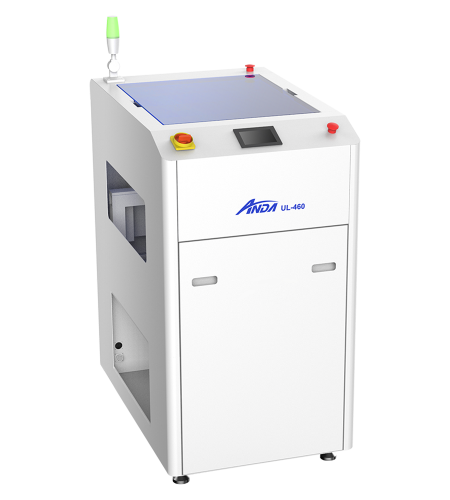

UL-460W Automatic PCB Flipper Inverter

Description

The Anda UL-460W automatic flipper is a compact inverting module for printed circuit boards (PCB) and pallet / carriers within an inline process. During operation, the pneumatic flipper smoothly inverts boards being processed for dual sided applications. Once inverted, the board assembly can continue on to the next work cell or return to the original work-station in a bi-directional mode.

Automate and/or customize your PCB assembly line with board conveyors, PCB loaders and unloaders, inspection conveyors, turn conveyors, flippers, inverters and more. Anda manufactures standard and custom board handling conveyors to improve and automate PCB assembly processes. Contact Us > with your board handling requirements or get answers to questions.

Automatic PCB Flipper Video Demo

Features of UL-460W Automatic Flipper Board Handling Conveyor

Standard Features:

- Robust steel frame construction

- Pin-chain edge conveyor

- Pneumatic board handling inverter

- Four-inch top and bottom side component clearance

- LCD front panel display with touchscreen

- Circuit board flip and return or pass-through mode

- Trouble alarm with sound, light tower indicator, and menu display

- Adjustable conveyor board width from 50 mm to 460 mm

- SMEMA communication interface

- CE certified

UL-460W Automatic Flipper PCB Handling Conveyor

| Transmission System | |

|---|---|

| Driving system | Micro Precision Speed Control Motor |

| Process Flow | L to R (Standard), R to L (Optional) |

| Conveyor Type | Chain |

| Conveyor Speed (XY) | 8 – 10 m/min |

| Conveyor Height | 900 ± 20mm (35.43” ± 0.79”) |

| Width Adjustment | Manual |

| Facility | |

| Standard Footprint | L 700 × W 1060 × H 1520 mm (L 27.56” x W 41.73” x H 59.84”) |

| Weight | 180 kg |

| Power | AC 220 V 50/60 Hz |

| Rated Power | 0.2 kW |

| Interface | |

| Controller | PLC with touch screen |

| Communication Protocol | SMEMA & IPC-CFX |

Related Products

ADJ-460

Link Conveyor

The Anda ADJ-460 buffer link conveyor is ideal for a wide range of PCB handling applications and can optimize Work-In-Progress (WIP) material flow during assembly, coating, dispensing and other processes.

ADJ-460UV

UV Inspection

The Anda ADJ-460UV is an ultra violet UV inspection station that allows manual/visual inspection of conformal coatings when applied to printed circuit board assemblies (PCBA).

SJ-460

Elevator

The Anda SJ-460 is an elevator PCB & pallet/carrier handling conveyor. This board handling machine lowers and elevates printed circuit board assemblies (PCBA) for lower return conveying and Anda One Man Operation (OMO) applications.