Fluid Dispensing & Jetting

Adhesive Dispensing & Jetting Valves

High Precision Fluid Dispensing Valves

Pneumatic Jetting Valve

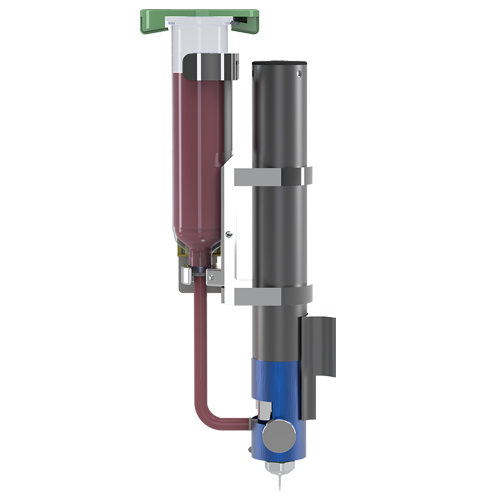

JET-8600

The Jet-8600 is a contactless jetting valve suitable for a wide range of fluid and adhesive dispensing applications which require high-speed precision with strict deposit tolerances. Fluid is dispensed onto substrates at speeds up to 200 Hz (dots per second) including assemblies with tight spaces without risk of collision because Z-axis is not required for jetting.

Applications: Adhesive Glues, Chip Package, Underfill, Pin Encapsulation, Dam & Fill, Edge Bonding & Encapsulation, Micro Coating| Jet-8600 Pneumatic Jetting Valve (Non-Contact) | ||

|---|---|---|

| Type | Pneumatic Jetting Valve | |

| Dimensions | 50 x 180 x 150 mm (2 x 7 x 5.9 in) | |

| Weight | 685 g | |

| Operating Pressure | ≥ 0.6 MPa | |

| Max Fluid Pressure | 0.3 MPa | |

| Max Operating Frequency | 200 Hz | |

| Minimum Dispensing Diameter or Volume | 0.2 mm (0.007 in) | |

| Flow Rate Range | – | |

| Max Viscosity Range | 250,000 cPs | |

| Max Heating Temperature | 80°C | |

Piezoelectric Jetting Valve

PV-20

The PV-20 is a high-speed precision contactless jetting valve designed for micro dispensing applications. Minimum dot size 0.2 mm, suitable for micro dispensing low to medium viscosity materials onto flexible printed circuit (FPC) and printed circuit board (PCB) assemblies requiring high-speed precision dispensing with strict deposit tolerances. Constant process control of dispensed materials at temperatures up to 150° C with dispensing speeds up to 1000 Hz (dots per second).

Applications: Adhesive Glues, Chip Package, Underfill, Pin Encapsulation, Dam & Fill, Edge Bonding & Encapsulation, Micro Coating| PV-20 Piezoelectric Jetting Valve (Non-Contact) | ||

|---|---|---|

| Type | Piezoelectric Jetting Valve | |

| Dimensions | 29 x 98 x 113 mm (1.2 x 3.9 x 4.5 in) |

|

| Weight | 500 g | |

| Operating Pressure | – | |

| Max Fluid Pressure | 0.3 MPa | |

| Max Operating Frequency | 1000 Hz | |

| Minimum Dispensing Diameter or Volume | 0.2 mm (0.007 in) | |

| Flow Rate Range | – | |

| Max Viscosity Range | 500,000 cPs | |

| Max Heating Temperature | 150°C | |

Auger Screw Dispensing Valve

SV-06

The SV-06 is designed for precise repeatable dispensing of solder pastes and other medium to high viscosity materials. Equipped with a quick release lure lock design, allowing it to with various needle sizes and multiple fluid types. A variety of auger screw pitch options are available to achieve faster flow or higher material precision deposits.

Applications: Adhesive Glues, Solder Pastes, Damping Greases, Pin Encapsulation, Dam & Fill, Thermal Conductive| SV-06 Auger Screw Valve | ||

|---|---|---|

| Type | Auger Screw Valve | |

| Dimensions | 57 x 109 x 278 mm (2.2 x 4.3 x 11 in) |

|

| Weight | 320 g | |

| Operating Pressure | – | |

| Max Fluid Pressure | 0.4 MPa | |

| Max Operating Frequency | – | |

| Minimum Dispensing Diameter or Volume | 0.05 μL | |

| Flow Rate Range | 1.38 – 160 μL/min | |

| Max Viscosity Range | 1,000,000 cPs | |

| Max Heating Temperature | – | |

Progressive Cavity Pump

PC-1000 / 2000

The PC1000 & 2000 are specialized screw valves which dispense one-component (1 K) or two-component (2K) materials with complete pressure-tight performance utilizing a specialized rotor-stator system. Controlled rotary motion gently dispenses material mediums without affecting structural performance through a displacement process which occurs in the stator, zero external forces are applied. Reverse flow material suck-back ensures controlled stop improving quality in dispensing results and provides mess-free easy maintenance.

Applications: Underfill, Pin Encapsulation, Dam & Fill, Metering, Ratio Mixing, Edge Bonding & Encapsulation| PC-1000 / 2000 Progressive Cavity Pump 1K or 2K Volume Valves | ||

|---|---|---|

| Type | Progressive Cavity Pump | |

| Dimensions | 33 x 33 x 246 mm 58 x 29 x 256 mm |

|

| Weight | 390 g/1100 g | |

| Operating Pressure | – | |

| Max Fluid Pressure | 0.6 MPa | |

| Max Operating Frequency | – | |

| Minimum Dispensing Diameter or Volume | 0.004 mL/0.01 mL | |

| Flow Rate Range | 0.01 – 6 mL/min 0.2 – 12 mL/min |

|

| Max Viscosity Range | 250,000 cPs | |

| Max Heating Temperature | – | |

Related Products

iJet-7H

The Anda iJet-7H is a multi-functional dispensing machine that delivers the highest operating speeds with a combined repeated accuracy of ±0.01 mm (10 µm) for high volume applications where speed, accuracy and precision are essential.

TSV Series

The Anda TSV Series is designed for offline tabletop selective coating and automated dispensing processes. This highspeed desktop dispenser series is extremely versatile making it ideal for low volume or laboratory applications.