Fluid Dispensing Machine

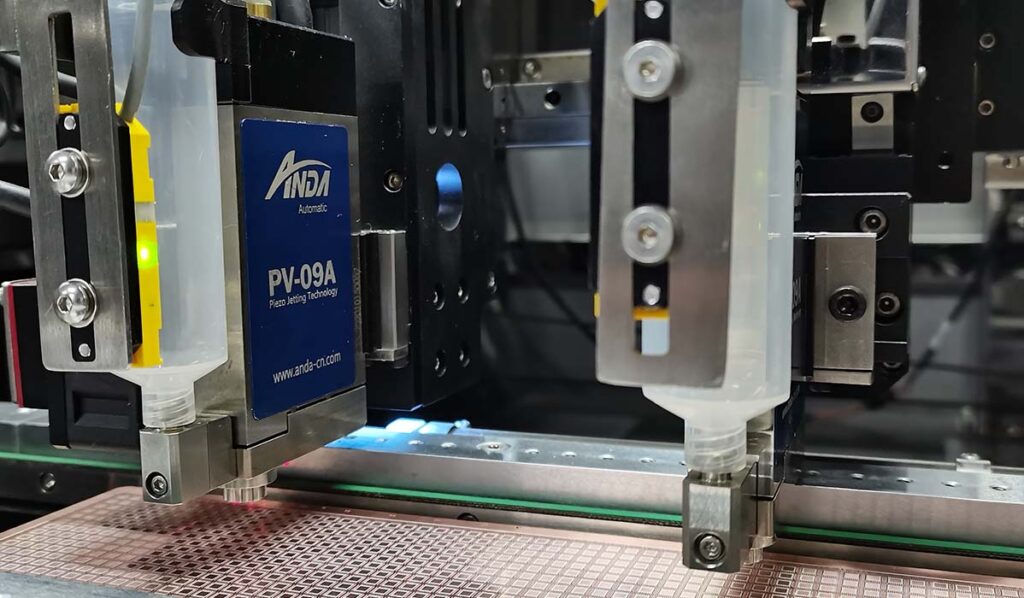

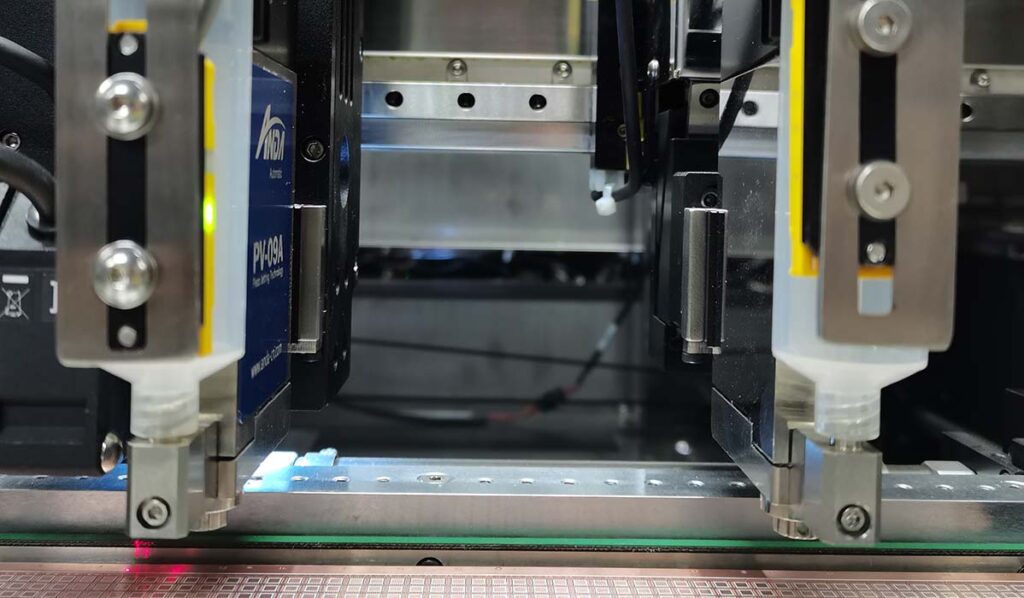

iJet-7H Precision High Speed Fluid Dispensing System

iJet-7H Fluid Dispensing Machine

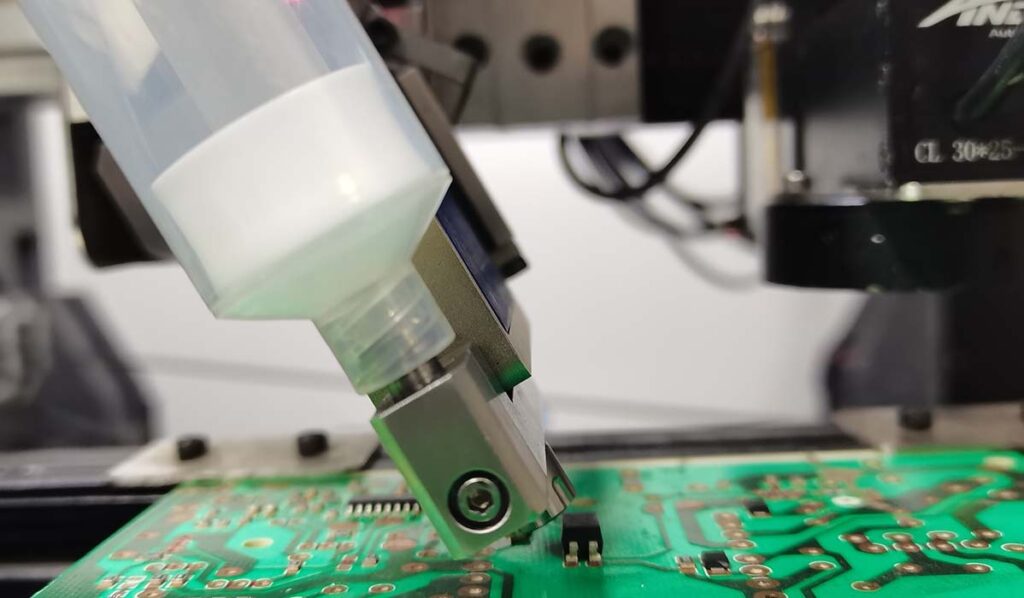

SMT underfill • Pin encapsulation • Surface Mount • Stack package POP • SMT red glue dispensing • dam & fill • FPC component reinforcement • Solder Paste • Solder Mask • Form in Place Gaskets

The iJet-7H is Anda’s flag ship high speed precision fluid dispensing system. This multi-functional dispensing machine delivers the highest operating speed with a combined repeated accuracy of ±0.01 mm (10 µm) for high volume applications.

The systems X&Y axes are equipped with linear motors and its Z axis a servo motor with ball screw actuator. The Anda User Interface software ensures fast dispensing speed and short cycle time. This machine is capable of dispensing adhesives and sealants.

Standard Features

- IPC and Windows OS control

- CCD visual positioning system

- Servo motor with ball screw

- Inline CCD visual programming or Gerber upload

- UPS and voltage stabilizer

- ESD grounding point

- CE certified

Optional Features

- Heated valves for viscosity control

- Tetragonal tilt

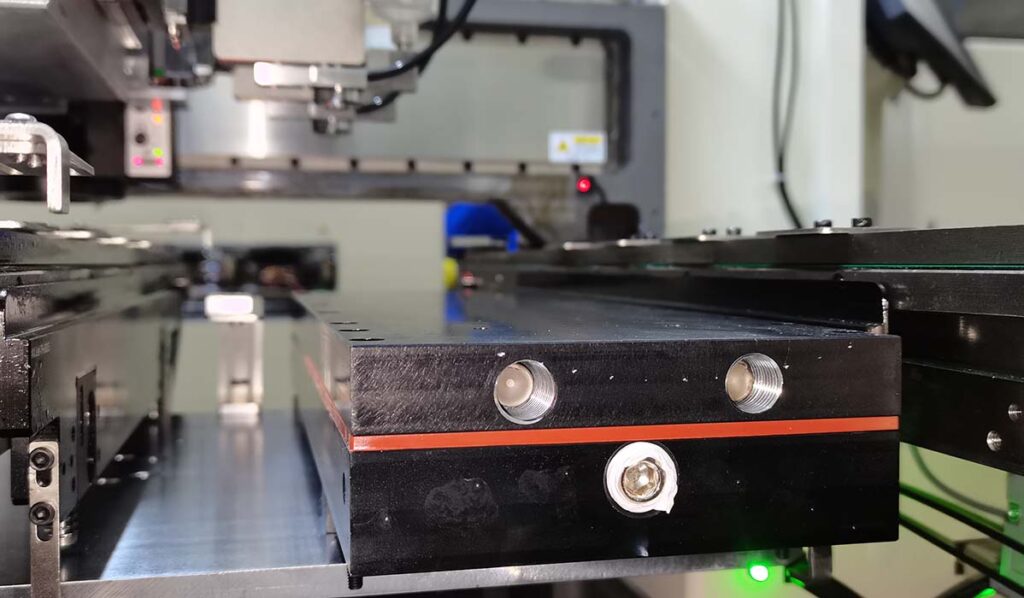

- PCB heater enhances material flow for underfill applications

- Precision weight measurement ensures accurate volumetric dispensing

- Laser height detection to calibrate Z axis automatically for component deformation

- Multiple valves available: Pneumatic Jet Valve, Slide Valve and Screw Valve

- Dual valves configuration for tuning with different glues and applications independently

iJet-7H Fluid Dispensing System Specifications

| Board Handling | |

|---|---|

| Standard Work Area (Single Conveyor & Valve) | X 400 x Y 480 x Z 30 mm (X 15.75" x Y 18.90" x Z 1.18") |

| Optional Work Area (Dual Conveyors & Valves) | X 340 x Y 220 x Z 30 mm (X 13.39"x Y 8.66" x Z 1.18") |

| Maximum Components Height | ± 30 mm(± 1.18") from PCB |

| Acceleration | 1.2 g |

| PCB Edge Clearance | ≥3 mm ( ≥0.12") |

| PCB Clearance Topside | 30 mm (1.18") |

| Max. Conveyor Width | 400 mm (15.75") |

| Min. Conveyor Width | 50 mm (1.97") |

| Fluid Volume | 30 cc |

| Fluid Level Sensor | Automatic monitor |

| Smart Auto Nozzle Cleaner | Non-contact vacuum nozzle cleaning |

| Transmission System | |

| Conveyor Quantity | 1 pair |

| Conveyor Type | Thermostable ESD belt |

| Process Flow | L to R (Standard), R to L (Optional) |

| Conveyor Height | 900 ± 20 mm (35.43" ± 0.79") |

| Conveyor Width Adjustment | Automatic (motorized) |

| Conveyor Speed (XY) | 2-13 m/min |

| Width Adjustment Speed | 250 mm/min |

| Max. Loading | 4 kg/m (even distribution) |

| Vision System | |

| Resolution | 1296 x 966 px |

| Pixel Size | 3.75 x 3.75 μm |

| Light Source | LED coaxial light source and ring light source |

| XYZ Axis Configuration | |

| No . of Valves | Single valve, Dual valves (option) |

| Motor | X & Y axes linear module, Z axis servo motor with ball screw actuator |

| Motor Power | DC 24V 69W x 2 |

| Maximum Speed | 1200 mm/s |

| Repeatability Accuracy | ± 0.01 mm (± 0.0004") 10 µm |

| Facility | |

| Standard Footprint | L 790 x W 1600 x H 1600 mm (L 31.10" x W 62.99" x H 62.99") |

| Weight | 700 kg (1540 lb) |

| Air Requirement | 0.6 Mpa |

| Extraction | ≥ 6.5 kg f/m³ |

| Input Power | AC 220V 50/60Hz |

| Rated Power | 2.5 kW |

| Interface | |

| Controller | IPC and motion control card |

| Software | Anda UI & Windows OS |

| Programming | On-line vision programming |

| Communications Protocol | SMEMA & IPC-CFX |

iJet-7H Fluid Dispensing Machine

Available Fluid Dispensing Machine Options

Related Dispensing Products

Dispensing Valves

Anda manufactures a variety of high precision fluid dispensing and jetting valves that can be utilized in many ways for various applications to perform high accuracy fluid dispensing and jetting.

TSV Series

The Anda TSV Series is designed for offline tabletop selective coating and automated dispensing processes. This highspeed desktop dispenser series is extremely versatile making it ideal for low volume or laboratory applications.

iCoat-3P

The Anda iCoat-3P is a three axes automated robotic metering and mixing machine that 3D dispenses single and multi-component compounds for a wide range of applications such as potting, encapsulation, etc.

Jet Fluid Dispensing FAQ

Jet fluid dispensing is a method of dispensing fluids in which a high-pressure stream of fluid is directed towards a target surface. This stream is created by a nozzle which is typically controlled by a computer to ensure precise and accurate fluid dispensing.

Jet fluid dispensing can be beneficial over other fluid dispensing methods as it can provide high precision and accuracy, it can be used for a wide range of fluids and viscosities, it can dispense very small droplets and it also can be automated.

Jet fluid dispensing systems utilize quality non-contact dispensing nozzles, control pressure and flow rates of the fluid material being dispensed and use precision gantry motion controls to improve the precision and accuracy of factory fluid material dispensing processes.

Jet fluid dispensing can be used for a wide range of fluids, including liquids, pastes, and gels. Some examples of fluids that can be dispensed using jet fluid dispensing include adhesives, inks, and lubricants.