CONFORMAL COATING VALVES

Conformal Coating Valves

Anda manufactures a variety of conformal coating machine valves. Our conformal coating valves can be utilized in a number of different configurations and spray patterns to meet manufacturing application requirements for coating of printed circuit board Assemblies (PCBA’s).

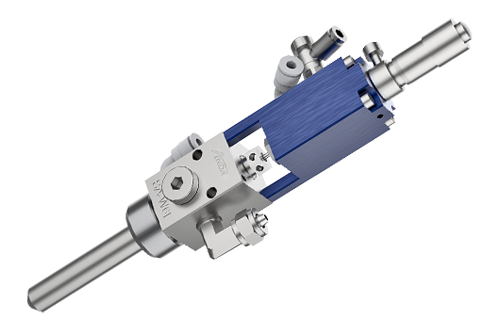

Atomized Conical Spray Valve

SA-W6L

Conformal Coating

The SA-W6L atomized conformal coating conical spray valve is the workhorse of the ANDA conformal coating nozzles. The SA-W6L can coat up to 80 to 100% of circuit boards depending on their complexity. It provides a repeatable, concentrated conformal coating film in a fine, circular cone spray pattern with coating widths ranging from 4 – 12 mm (0.15 ~ 0.5 in).

SA-W6L Atomized Conformal Coating Conical Spray Valve |

||

|---|---|---|

| Dimensions | 202 x 60 x 30 mm (8 x 2.4 x 1.2 in) | |

| Weight | 280 g | |

| Viscosity Range | 30 – 3,500 cPs | |

| Fluid Dispense Technology | Divorced Needle Valve with Atomization | |

| Dispense Pattern | Cone Shaped | |

| Dispense Width | 4 ~ 12 mm (0.15 ~ 0.5 in) | |

| Operating Pressure | 0.4 – 0.7 Mpa | |

| Fluid Pressure | 0 – 0.5 Mpa | |

| Working Frequency | ≥ 400 per min | |

| Medium | Clean Dry Compressed Air or Nitrogen (filtered & oil free) | |

| Operating Temperature | Ambient | |

| Control | High Speed Solenoid Valve | |

| Fluid Inlet | Compression Fitting | |

| Applied Fluid | Acrylic, Urethane, Silicone, Epoxy Conformal Coatings | |

| Features & Benefits | The Divorced Needle Seat Design reduces adhesive residue and minimizes maintenance. Fluid and Atomization Pressures are individually adjustable. Coating Thickness from ~10 to 200 microns. | |

| Applications | Electronics Packaging, Lighting, Automotive, Medical, Military, Aerospace and Energy Industries | |

Needle Dispense Valve (Non-Atomized)

DJ-01

Fluid Dispensing, Conformal Coating, Potting, Encapsulation

The DJ-01 needle dispense valve (non-atomized) is a versatile dispensing valve for single-component bead, dot, potting, conformal coating or encapsulation projects. The DJ-01 is most commonly used in junction with the SA-W6L to conformal coat complex areas of circuit boards that are hard to reach and require a higher degree of accuracy. Dispense widths of 1 – 2 mm (0.04″ – 0.08″) and accepts a wide range of replaceable tips.

DJ-01 Needle Fluid Dispensing Valve (Non-Atomized) | ||

|---|---|---|

| Dimensions | 182 x 83 x 55 mm (7.2 x 3.3 x 2.2 in) | |

| Weight | 260 g | |

| Viscosity Range | 30 – 20,000 cPs | |

| Fluid Dispense Technology | Divorced Needle Valve (Non-Atomized) | |

| Dispense Pattern | Fine Needle Dispense | |

| Dispense Width | 1 – 2 mm (0.04 – 0.08 in) based on needle tip size | |

| Operating Pressure | 0.5 Mpa | |

| Fluid Pressure | 0 – 0.5 Mpa | |

| Medium | Clean Dry Compressed Air or Nitrogen (filtered & oil free) | |

| Operating Temperature | Ambient | |

| Control | High Speed Solenoid Valve | |

| Fluid Inlet | Compression Fitting | |

| Applied Fluid | Acrylic, Urethane, Silicone, Epoxy Conformal Coatings & Gels | |

| Features & Benefits | The Divorced Needle Seat Design reduces adhesive residue and minimizes maintenance. Coating Thickness from ~10 to 200 microns. | |

| Applications | Electronics Packaging, Lighting, Automotive, Medical, Military, Aerospace and Energy Industries | |

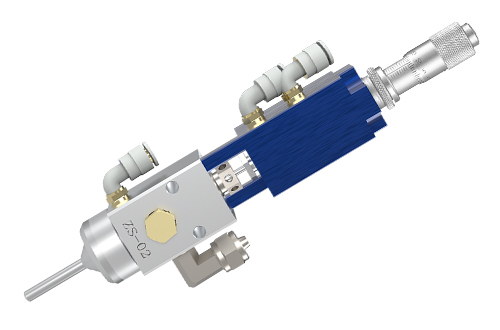

Atomized Needle Valve

ZS-02

Conformal Coating

The ZS-02 atomized conformal coating needle valve is a highly versatile conformal coating applicator that supports a wide range of fluid viscosities and is ideal for solvent or non-solvent fluid formulations. It is specifically optimized to atomize coating materials delivering an ultrafine needle spray pattern 2 – 5 mm (0.08 – 0.2 in) with exceptional edge definition and uniform coatings at high speeds. Long service life and improved design reduces the sealing ring replacement frequency for easy maintenance.

ZS-02 Atomized Conformal Coating Needle Valve | ||

|---|---|---|

| Dimensions | 202 x 60 x 30 mm (8 x 2.4 x 1.2 in) | |

| Weight | 280 g | |

| Viscosity Range | 30 – 3,500 cPs | |

| Fluid Dispense Technology | Divorced Needle Valve with Atomization | |

| Dispense Pattern | Needle | |

| Dispense Width | 2 – 5 mm (0.08 – 0.2 in) | |

| Operating Pressure | 0.5 Mpa | |

| Fluid Pressure | 0 – 0.5 Mpa | |

| Working Frequency | ≥ 400 per min | |

| Medium | Clean Dry Compressed Air or Nitrogen (filtered & oil free) | |

| Operating Temperature | Ambient | |

| Control | High Speed Solenoid Valve | |

| Fluid Inlet | Compression Fitting | |

| Applied Fluid | Acrylic, Urethane, Silicone, Epoxy Conformal Coatings | |

| Features & Benefits | The Divorced Needle Seat Design reduces adhesive residue and minimizes maintenance. Fluid and Atomization Pressures are individually adjustable. Coating Thickness from ~10 to 200 microns. | |

| Applications | Electronics Packaging, Lighting, Automotive, Medical, Military, Aerospace and Energy Industries | |

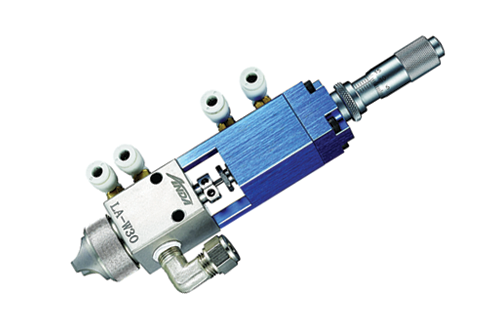

Atomized Wide Spray Valve

LA-W30

Conformal Coating

The LA-W30 atomized conformal coating valve is ideal for quickly delivering uniform coatings to wide areas on substrates. This atomized valve delivers a wide fan-shaped pattern of coatings with widths ranging from 15 – 50mm (0.6 – 2 in). Long service life and improved design reduces the sealing ring replacement frequency for easy maintenance.

LA-W30 Atomized Conformal Coating Fan Spray Valve |

||

|---|---|---|

| Dimensions | 150 x 58 x 25mm (5.9 x 2.3 x 1 in) |

|

| Weight | 260 g | |

| Viscosity Range | 30 – 3,500 cPs | |

| Fluid Dispense Technology | Divorced Needle Valve with Atomization | |

| Dispense Pattern | Fan Shaped | |

| Dispense Width | 15 – 50 mm (0.6 – 2 in) | |

| Operating Pressure | 0.5 Mpa | |

| Fluid Pressure | 0 – 0.5 Mpa | |

| Working Frequency | ≥ 400 per min | |

| Medium | Clean Dry Compressed Air or Nitrogen (filtered & oil free) | |

| Operating Temperature | Ambient | |

| Control | High Speed Solenoid Valve | |

| Fluid Inlet | Compression Fitting | |

| Applied Fluid | Acrylic, Urethane, Silicone, Epoxy Conformal Coatings | |

| Features & Benefits | The Divorced Needle Seat Design reduces adhesive residue and minimizes maintenance. Fluid and Atomization Pressures are individually adjustable. Coating Thickness from ~10 to 200 microns. | |

| Applications | Electronics Packaging, Lighting, Automotive, Medical, Military, Aerospace and Energy Industries | |

Thin Film Coating Valve (Non-Atomized)

IC-100L

Thin Film Conformal Coating

The IC-100L thin film conformal coating valve provides precision and dependability to the application of conformal coating materials. With virtually 100% transfer efficiency, the film coating applicator improves conformal coating material utilization. Reduced coating thicknesses offer further material cost savings. Non-atomized 6 – 19mm (0.24 – 0.75 in) coating width for low viscosity conformal coatings (100 cPs or less).

IC-100L Thin Film Conformal Coating Valve (Non-Atomized) | ||

|---|---|---|

| Dimensions | 195 x 94 x 71 mm (7.7 x 3.7 x 2.8 in) | |

| Weight | 520 g | |

| Viscosity Range | ≤ 100 cPs | |

| Fluid Dispense Technology | Thin Film Coating (Non-Atomized) | |

| Dispense Pattern | Fan Shaped | |

| Dispense Width | 6 – 19 mm (0.24 ~ 0.75 in) | |

| Coating Thickness | 0.01 – 0.076 mm (10 – 76 µm) | |

| Edge Tolerance | ± 0.75 mm (0.03 in) | |

| Operating Pressure | 0.55 Mpa | |

| Fluid Pressure | 0.1 – 0.4 Mpa | |

| Medium | Clean Dry Compressed Air or Nitrogen (filtered & oil free) | |

| Operating Temperature | Material Heating | |

| Control | High Speed Solenoid Valve | |

| Fluid Inlet | Compression Fitting | |

| Applied Fluid | Conformal coating materials with viscosities 100 centipoise or less | |

| Features & Benefits | Wet coating thicknesses range from 125 to 750 µm (0.5 to 3 mils) for solvent-based materials and 0.1 to 0.2 mm (4 to 8 mils) for 100-percent solid materials.The IC-100L heated, circulating fluid system provides closed-loop temperature control and allows viscosities to remain independent of the ambient environment. | |

| Applications | Electronics Packaging, Lighting, Automotive, Medical, Military, Aerospace and Energy Industries | |

Related Products

iCoat-3 Series Conformal Coating Machine

The Anda iCoat-3 selective conformal coating machine is a three axes gantry (X,Y,Z) system designed to strike a balance between cost and performance.

iCoat-5 Series Conformal Coating Machine

The Anda iCoat-5 is a top-tier precision selective conformal coating machine with five axes gantry (X,Y,Z,U rotation) + 35° tilt and running accuracy of 0.02mm (20 µm).

iCoat-6 Series Conformal Coating Machine

The Anda iCoat-6 is a thin film conformal coating system with continuous fluid heating to ensure set fluid viscosity for coating.